Today we almost finished the strip grinding. Just a few strips to finish next time.

However I have done a lot of other preparations.1. Redesigned the height adjustment of the router table. Worked OK Before, but a little redesign of the height adustment screw mechanism makes it easier to adjust height. Also made a locking unit to safely lock the height after proper adjustment.

2. Made the final clamps we will use when glueing strips. Special clamps to secure strip to forms and also clamps to hold the strip firmly against the previous strip. About 70 of each. (for making my Solo Day and also my friends double kayak and small solo canoe)

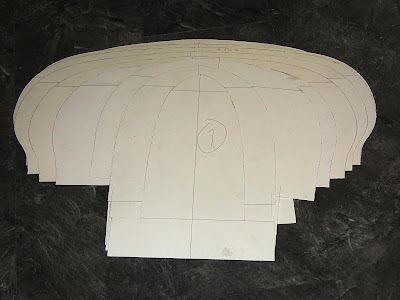

|

| Clamps to hold strips |

3 Measured my old strongback and found that it had warped into both a banana and a propeller shape. Construction was a simple board ontop of 2 planks. Went into the recycling bin.

So... Just make a new, better one. This time I made a telescopic box construction. 2,5m-4m (8´-13´). Undercarriage on lockable Wheels.

|

| New strongback |

Forms will be clamped to the strongback by a clamp made of long threaded screws with a crossbar and wingnuts at the bottom. Easy adustment and no screws in the strongback. There will be a submerged track in the center of the strongback where I will put a thin string to get an exact centerline.

|

| Form mounted by a clamp |